A sagging gate is more than an annoyance. It’s usually the first visible sign that something in the fence system (post, hinges, frame, hardware, or footing) wasn’t sized or installed to carry real-world loads: gravity, wind, freeze/thaw, and daily use. The payoff of fixing this correctly is big: a gate that closes cleanly, doesn’t scrape, and stays square for years. Before we break down the most common ways gates sag, and how you can check for these issues, it's important to understand what causes them and how to spot the signs early when assessing modern gate systems in Canada/North America (especially privacy fence and fence panels). This guide will show you what actually causes sagging, and the practical checks to confirm it before you spend money twice.

What is gate sag actually?

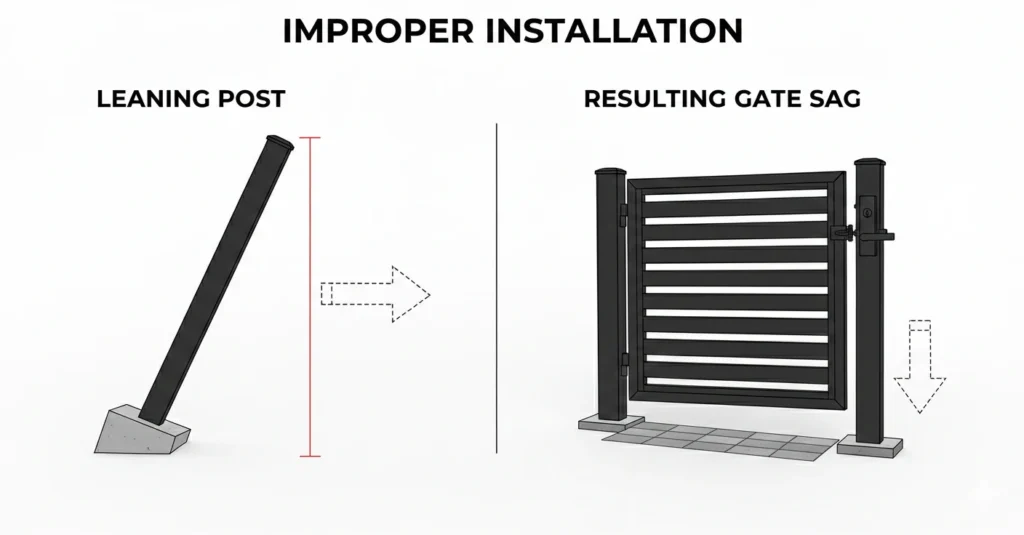

Most people assume the gate is the problem. Often, the gate post is the problem. Sagging is typically indicated by one or more of the following: The latch-side bottom corner drops and drags. The latch misses the strike plate unless you lift the gate. Gaps change seasonally (worse after winter). The hinge-side post leans or twists slightly over time. In other words, the gate is a cantilevered load. If the hinge-side support moves even a little, the gate magnifies that movement into a visible sag.

How to diagnose a sagging fence gate in 10 minutes (quick how-to)

Bring: a level, a tape measure, and a few shims/blocks.

Step 1: Check the hinge post first

- Put a level on the hinge post (front-to-back and side-to-side).

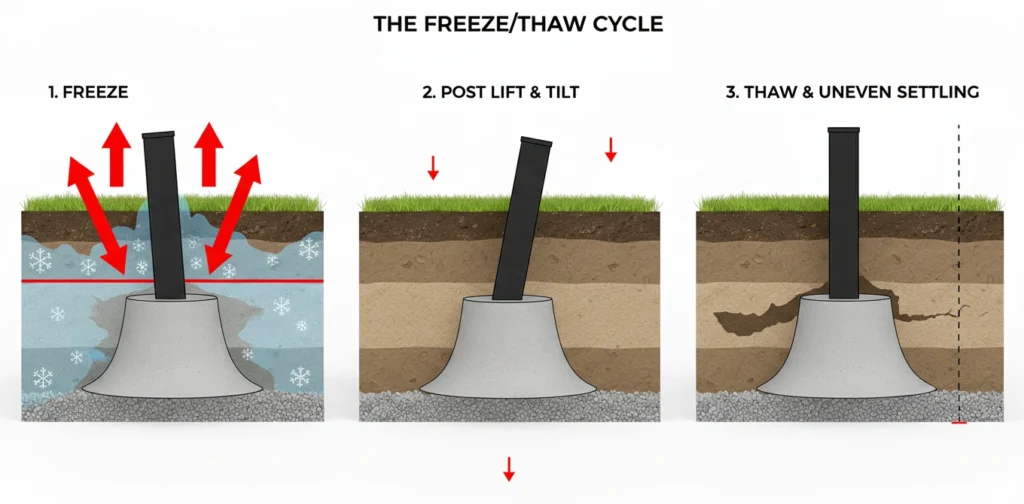

- If it’s out of plumb, the “sag” may actually be post-lean (common after freeze/thaw if footing depth/drainage is wrong). Post movement is a classic result of not setting posts deep enough below frost level in colder climates.

Step 2: Check hinge fasteners and hinge spacing

- Look for loose fasteners, wallowed-out holes, or crushed material under hinge plates.

- When hinges are undersized or low-quality relative to the gate weight, sagging is a predictable result.

Step 3: Check if the gate frame is staying square

- Measure both diagonals corner-to-corner.

- If the two diagonal measurements are not equal, the frame is ‘racking’, twisting under load so it is no longer square.

Step 4: Check the ground clearance and swing path

- If the grade rises under the swing or the ground heaves seasonally, the gate will scrape even if it’s built well.

Quick read: If the post is leaning → fix the post/footing. If the post is solid but the diagonals changed → fix the bracing/frame and hardware.

The fence system mistakes that cause gate sag

1) Undersized or poorly set gate posts (the #1 root cause)

A gate post takes dynamic loading, that is, varying force, each time the gate opens or closes. In cold climates, shallow footings (the concrete bases supporting the post) can shift due to frost heave, which occurs when soil expands as it freezes, especially when drainage is poor. Practical guidance commonly emphasizes digging below the frost line, the depth below ground where soil does not freeze, to reduce heave risk.

Mistakes that lead to sag:

- Shallow post depth (especially for gate/terminal posts)

- No proper concrete footing (or inadequate base/drainage)

2) “Random parts” gate builds (mismatched hardware + frame + posts)

A gate is not just a panel with hinges; it is a small structure. When components such as post size, hinge type, frame stiffness, and latch alignment aren’t designed to work together, tiny tolerances become recurring sources of adjustment.

This is why modern aluminum fence systems and gates perform best when posts/rails/panels/hardware are engineered as a matched kit (not mixed from whatever is on the truck). PrimeAlux explicitly positions its fencing and gates as a system approach, with panels, posts/rails, and accessories designed to match.

3) Wrong bracing strategy (or bracing that can’t actually carry a load)

Diagonal bracing is not “decoration.” A properly laid-out brace helps keep a gate square and transfers the load in a way that hinges and posts can handle. Many “anti-sag” fixes fail because they’re installed in a way that doesn’t meaningfully carry compression/tension where needed (or they’re treated as a substitute for a stable post).

Common mistake: relying on a light cable/turnbuckle to “fix” a gate that’s sagging because the post is moving.

4) Over-wide gates without an upgraded structure

The wider the gate, the more leverage it applies to the hinge post and hardware. If you increase width/weight without upgrading post size, hinges, and frame stiffness, sag becomes inevitable.

PrimeAlux’s standard aluminum gate sizes are 3’×6’ and 4’×6’ (post-center measurements), with heavy-duty hinges and a latch included in the kit. Larger sizes are available with the appropriate hardware and structure.

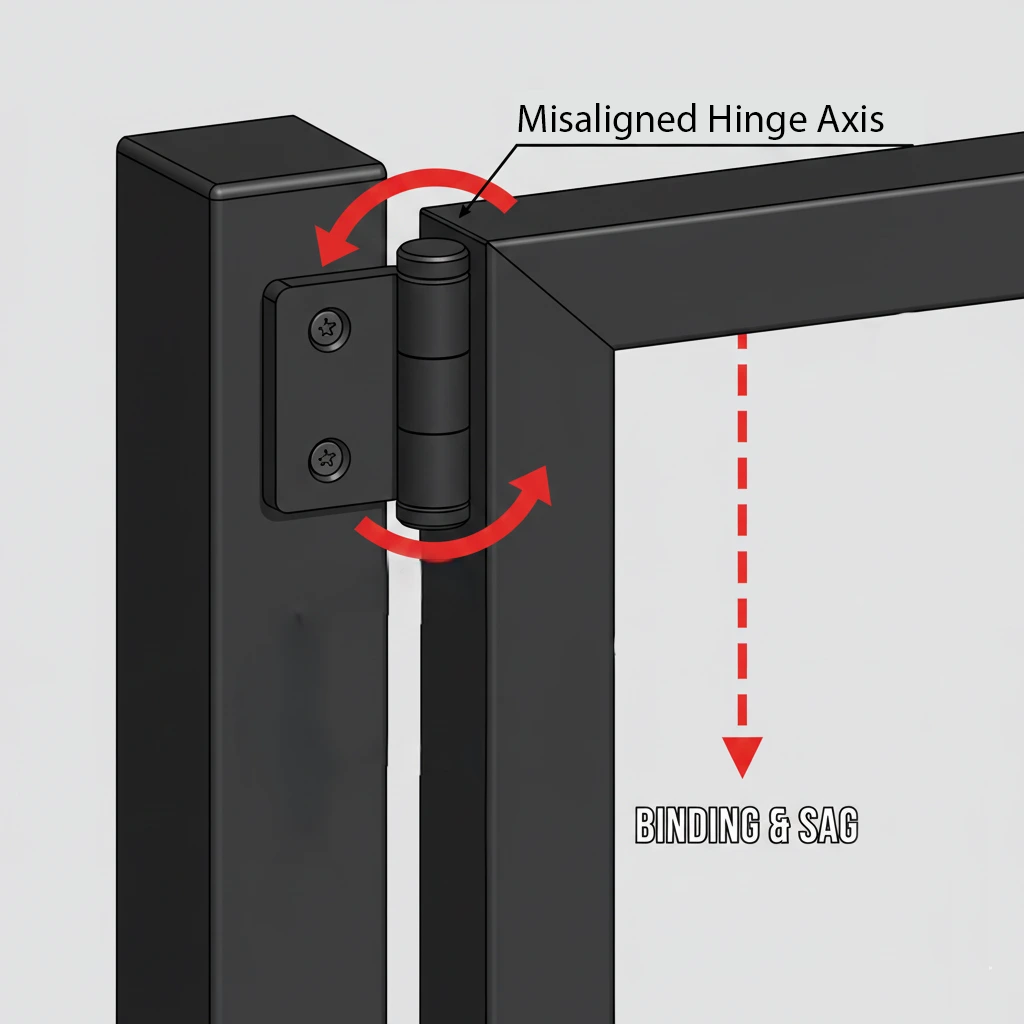

5) Installation tolerances: hinge alignment, spacing, and latch setup

Even a strong gate sags if hinge placement and alignment are sloppy:

- Hinges not aligned on the same axis.

- Fasteners not seated correctly.

- Latch installed without allowing for seasonal movement and settlement.

6) Freeze/thaw + drainage ignored (the “it was fine last summer” problem)

In Canada and the Northern US, freeze/thaw cycles. Changes between freezing and thawing that expand and contract the soil, and saturated (water-filled) soil, make post-movement worse. Guidance commonly recommends digging post holes deep enough below the frost level (the point in the ground that typically freezes) and wide enough for solid concrete support.

Gate width: when to upgrade

If you’re going wider/heavier than a typical pedestrian gate:

- Upgrade hinge hardware (more capacity, more fasteners, better bearing surfaces)

- Consider additional reinforcement/crossbars.

- Ensure that post sizing and footing are designed for the leverage.

Hardware and specs: what to look for in modern aluminum fences and gates

If you’re shopping for fence panels and gates as part of one system, look for clarity on:

Gate post + hinge hardware

- “Heavy-duty hinges” should be paired with a post spec and installation method (surface vs in-ground) that supports them. PrimeAlux calls out heavy-duty hinges/latches and a modular surface or in-ground setup.

Frame stiffness

- A stiff frame resists racking (diagonal distortion). PrimeAlux describes reinforced crossbars and a modular frame approach.

Fence panel system compatibility

For privacy fence systems in particular, you want the gate to match the fence panel system geometry and loads, same design language, same tolerances, compatible hardware.

PrimeAlux’s privacy fence product page lists a foam-core aluminum panel system with reinforced rails and aluminum extruded posts, which is the kind of “system thinking” that reduces misalignment and callbacks when gates are integrated.

Costs: what sagging gates really cost (and what “cheap installs” skip)

You don’t need exact prices to understand the economics:

The hidden cost is usually the callback.

Sagging gates trigger:

- Re-hanging labor

- Hardware replacement

- Post correction (often the most disruptive)

- Landscaping repairs around footings

What low quotes often skip

- Proper gate-post depth/footing strategy for freeze/thaw regions

- Matched hardware sized for the gate weight/width

- A repeatable installation method with a manual/checklist

Practical checklists

Checklist: “Before you buy” questions for any fence company near me

- Will the gate be built as a matched kit (posts/hinges/frame/latch), or assembled from mixed parts?

- What’s the gate-post strategy for cold climates (depth below frost line, drainage, footing size)?

- How will the gate be kept square over time (frame reinforcement + bracing strategy)?

- Do you provide installation documentation/manuals?

- How do you handle alignment tolerances (hinge axis, latch alignment, clearance)?

Checklist: “On-site install” red flags (common mistakes)

- Hinges installed without consistent alignment

- Gate frame not checked for square (diagonal measurement)

- Grade under swing is not considered.

- No documented install method, just “we’ve always done it this way.”

Finally, for those wanting a clear example of system engineering, here’s the PrimeAlux perspective on quality aluminum fence systems, including how this approach prevents common gate and fence issues.

If you’re comparing gates and privacy fence options, PrimeAlux’s positioning is essentially: performance comes from system engineering, not just material claims.

Here’s what that means in practical terms:

- Matched system design

- PrimeAlux emphasizes panels, posts/rails, and accessories as a designed set, because mismatched components are a common cause of movement, sag, and hardware issues.

- Documentation over marketing

- PrimeAlux publishes technical resources (including wind-load testing, fire testing, OBC-related documentation, load testing, and acoustical testing) and also provides cleaning and maintenance guidance.

- (If you’re comparing brands, being able to request and review documentation is a strong signal that the company expects its system to be evaluated objectively.)

- Gate integration matters

- PrimeAlux’s gate page frames gates as compatible with the fence systems, with specified post size, hardware, and standard gate sizing.

- That “kit mindset” is exactly what reduces sag risk compared with gates built from random parts.

Frequently Asked Questions

Freeze/thaw can move posts if they aren’t set deep enough below the frost line or if drainage/footings allow heave.

Often the post. Hinges can loosen, but a slight post-lean creates a big visible sag. Start the diagnosis by checking the plumb on the hinge post.

Sometimes, if the post is stable and the gate frame is out of square, or the hardware is undersized. If the post is moving, “hardware fixes” often become temporary.

Bracing should be designed to keep the frame square under gravity load. Many pros emphasize correct diagonal bracing principles rather than relying only on a cable/turnbuckle.

They can, if the post/footing, or the hardware, isn’t sized correctly. Material helps, but system design and installation matter most.

Ask how gate posts differ from line posts (depth, footing, drainage, reinforcement) for your climate. If the answer is vague, be cautious.

They can increase wind load and overall system loads, so post strategy and hardware sizing matter more. PrimeAlux highlights evaluating systems with documentation/test data rather than generic claims.

Of course! Our showroom and pickup location is at:

2222 South Sheridan Way, Unit 116, Mississauga

Serving Vaughan and the GTA.